Early Supplier Involvement: A Prominent Example of Agile Procurement Process

Early Supplier Involvement to the rescue from bad supplier sourcing

In many companies, the procurement process remains a disappointment for internal stakeholders and suppliers. All-purpose RFPs and blanket e-auctions may put governance above business interests and demotivate suppliers unless consciously applied to appropriate categories.

The need for an agile procurement process is undeniable. The entire industry revolted, wanting to kill the RFP and claiming billion-dollar losses from outdated sourcing approaches.

Nowadays, everyone carols about Agile procurement and sourcing but forgets to explain it. Alternatively, our intention is not to generalize but suggest fine working examples.

This post will elaborate on Early Supplier Involvement, which demonstrates virtues of true agility - trust, cooperation, flexible governance, and a value-centric mentality.

Early Supplier Involvement (ESI)

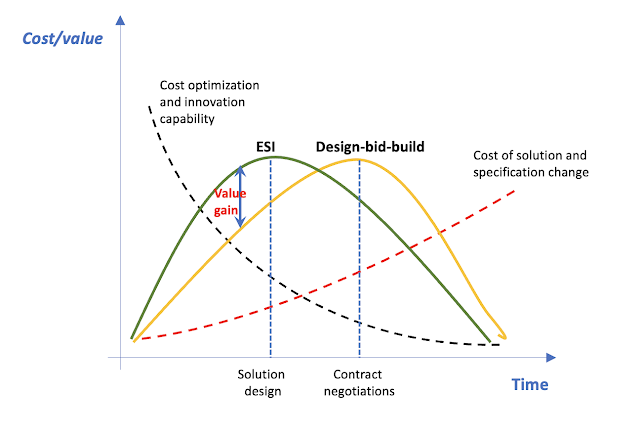

ESI resides on a simple premise - the early involvement of critical suppliers in the product or service design process enables better supply risk management and avoidance of late changes to the design and specifications and associated costs and delays.

The bulk of product cost is in its design and the choice of materials. This is where the unparalleled cost-saving potential remains.

Therefore, the development of new products went beyond organizational boundaries to find external sources of knowledge and levers for cost optimization.

Just as with any other concept, ESI is no magic bullet.

It poses threats of supplier opportunism, inter-organizational conflicts, and even delays of new product introduction due to the increased complexity of the design process.

Nevertheless, some benefits of ESI could hardly be compromised:

- access to innovation,

- leveraging supplier capabilities and resources,

- early detection of technical and manufacturability issues to avoid costly design and specification changes.

Tapping to the innovation power of the supply base is a systematic way to increase the firm's own innovation capabilities.

The famous resource-based view from the Theory of the Firm assumes that its performance depends on the resources it has in possession. The way these resources are used and configured enables performance and can provide a distinct competitive advantage.

ESI is one of the ways to acquire critical resources and leapfrog the competition.

ESI in practice

No reason to further argue the pros and cons of ESI. Some companies have already been using this concept for many years.

For example, ESI applied in the construction industry becomes ECI - Early Contractor Involvement.

Since the early 2000s, contractors have contributed their construction knowledge and expertise in public infrastructure projects in the US, UK, Australia, Netherlands, and Norway.

ECI can occur in the internal planning, design, and project execution phases.

By the way, the procurement phase of an ESI project can be conducted according to the Best Value Procurement concept we explained in this post.

Some owners have developed relationship-based ECI models for the whole life

cycle of the project. Other owners start with a collaborative approach in the early phase of a project (pre-delivery) and move to a conventional type of contract in the project execution phase.

The hybrid ECI model comprising a relationship-based pre-delivery and conventional delivery stages recalls the pre-commercial procurement concept for innovation projects, which we described in section 8 of this post.

In pre-commercial procurement, the selection of suppliers happens based on the material evidence of their delivery capabilities - solution design, prototype, and then the first test product. Upon acceptance of results, a customer embarks on the standard RFP process to select the innovation product's full-scale delivery partner(s).

ESI is nothing new in the procurement world. It has been out there for decades - yet another proof that Agile is an old dog with new tricks.

Nevertheless, the beauty of ESI is that it requires more of a cultural shift than a new skill set. It comes with trust, relationship building, and importantly an absorptive capacity, i.e., an ability to learn from suppliers.

Agile sourcing and procurement are more complicated than it sounds, just as becoming confiding, upholding, and receptive on the personal front. We all know it's utterly essential, maybe just not timely or somewhat inconvenient, or whatever other excuses are there.

Let's at least envy the son of the mother's friend, who's practicing it as we speak.

P.S. If you appreciate hundreds of hours invested in researching and writing this blog, you can buy me a coffee or subscribe for the membership by following this link. Thank you!

More information on this and other exciting topics could be found in "The Technology Procurement Handbook." It represents 23 years of experience, billions of dollars worth of successful sourcing projects, and 1000s of hours spent on research, analysis, and content creation for the most demanding professional readers.

Comments

Post a Comment